Services

Automation and mechanization of production offer many benefits to the manufacturers and producers resulting

in higher efficiency, important cost reduction and reduces the needs of human resources.

| Automation | Special Projects | Support |

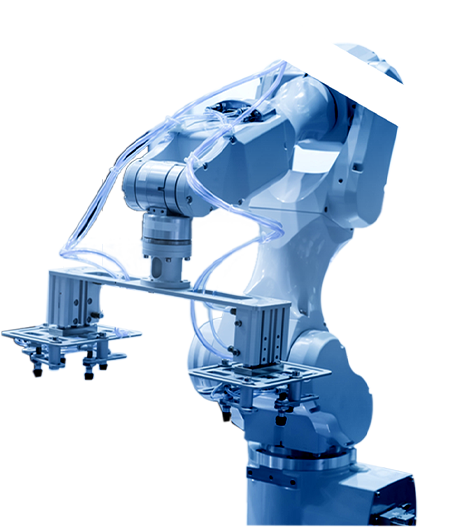

Automation

Custom made production of machines and equipment is designed and manufactured

according to the individual requirements of the customer. We design technology for you

to meet the required parameters for the manufacturing, assembly and quality of your product. Our demonstrated experience from real projects and know-how guarantee that our specialized technological equipment completely meets your expectations.

- Unique concept and design

- From simple product assembly to large automated technological units

- Applications in non-traditional fields

- Applications of special technologies

- R&D projects and prototype equipment

- Advanced/intelligent assembly lines

Click and see fields of automation

Special-purpose machines

To the programme of the company KSB belongs development, production and delivery of special-purpose machines and equipment. Involved are not standardly produced machines and therefore they are „made to order„ according to the technical order of a customer. Our special purpose machines operate in various industry – engineering, defence, pharmaceutical, food, automotive, electrotechnical etc.

Automatic control system

Robotized workplaces

Automatic assembly lines

Complex production lines

We design and manufacture equipment that is technologically and spatially adapted to the client’s environment.

Special projects

One of the main capabilities of our company KSB is the experience and knowledge in design a development of the special machinery and production lines intended for the use in explosive environment production, where the explosive atmosphere is contains gases, vapours or dusts.

The design and construction of such an equipment should be in accordance with the operating parameters and ensure a very high level of protection (according the directives of the local government, European Union or different state authorities).

The machinery and equipment developed for the explosive environment production is mainly used by chemical, mining or defence industry as well as automotive industries. Our machines are intended for the production of airbags and seatbelts pyrotechnical units, detonators for mining and demolition works, production and disposal of ammunition.

Click and see special projects

Ammunition production lines and machinery

- Complete production lines of small, medium and large calibre ammunition

- Automation of standard production processes

- Machines and assembly lines for production of ammunition components:

- Fuses, primer screws, igniters, detonators, time delay unit for fuses, etc.

- Visual control and mechanical measuring systems automation

- Automatic machines for marking, stamping and packing

- Automatic explosives weighing and feeding systems

- Various unique turnkey solution

- Pressing of thermobaric explosive

- Welding in explosive environment

- Riveting in explosive environment (reactive armour)

Machines for production in explosive environment

- Machines for production of the pyrotechnical Initiators for critical automobile safety systems components (airbags, seatbelts and other protection mechanism)

- Machines for pressing explosive and pyrotechnical composition

- Boosters, ignitors, detonators, time delay units, etc.

- Automated quality control systems including state-of-the-art visual monitoring & measuring

- Machinery and complete production line for pyrotechnics and fireworks

- Ultrasound welding, riveting in ex. Environment

Support

We offer to our partners modern, creative and flexible solutions, supported

by experienced team of specialists. Our references of successfully realized projects come

from various fields of industry.

Click and see provided services

Consultancy and advisory

Project management and realization

- Identifying and understanding customer needs – based on communication with the customer, we define:

- subject of production, including specific requirements for dimensions and material and other specific product details

- environment, layout and area of machine placement

- Suggestion of solution – based on the analysis, our engineers propose and design a suitable production automation solution

- determining dimensions of the machine

- calculating efficiency – time and cost savings

- commercial and technical offer

- Design and engineering – after proposal approval

- Engineering work

- 3D model creating

- Technical documentation

- List of material etc.

- Production

- Production and assembly of the machines and equipment

- Commissioning at customer facility

- Delivery to customer place

- Installation and pilot start-up

- Training of production personnel and maintenance staff

-

- Maintenance of equipment

- Spare parts deliveries and after sales support

- Upgrades and modernization of machines & equipment

Aftersales support

KSB provides to its customers and partners a long-term support after delivery of the product by:

- Online support and technical team response

- Warranty and after-warranty service

- Standard and preventative maintenance

- Delivery of spare parts and components

- Repairs & overhaul

- Modernization and modification of current equipment

Modernization and repair

- Modernization, modification and overhaul of current equipment

- Standard and preventative maintenance and repairs